Aqualabo is a major player in aquaculture by offering for more than 20 years products such as portable oxymeters and sensors for the control of dissolved oxygen levels in fish farms. Based on our experience and our proximity to our customers, we have been offering for more than 6 months an oxygen sensor in plastic version (OPTOD plastic) at competitive price point.

Based on our discussions with users and to better support you in the maintenance constraints related to aquaculture, we have decided to test several solutions to limit the fouling of the sensors and facilitate their cleaning.

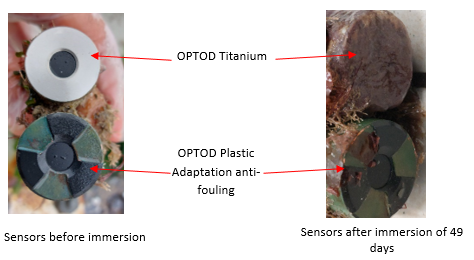

In this study, we compared the performance of an OPTOD titanium version and a plastic OPTOD on which an anti-fouling adaptation was installed. The two sensors were then installed at Base de Lorient (France-Morbihan 56), within the Course au Large pole, in sea water immersion for two measurement campaigns of about 40 days (August to September 2022).

First measurement campaign from August 28 to October 10, 2022

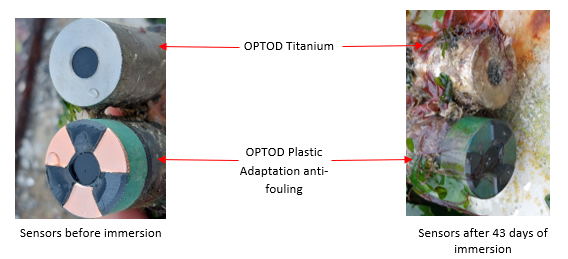

The first measurement campaign took place from 28 August to 10 October without any maintenance during the 43 days. The sensors were combined with an ODEON (portable multiparameters) and the temperature and dissolved oxygen data were continuously recorded with a 2-minute scan time step.

After 43 days of immersion, the bodies of both sensors are covered with algae and the head of the OPTOD Titanium sensor is covered with biofilm and algae. Although the body of the plastic OPTOD sensor is also covered with algae, the anti-biofouling strainer and especially the active pellet are in a very satisfactory state, free of biofilm allowing the sensor to continue to measure oxygen levels with reliability.

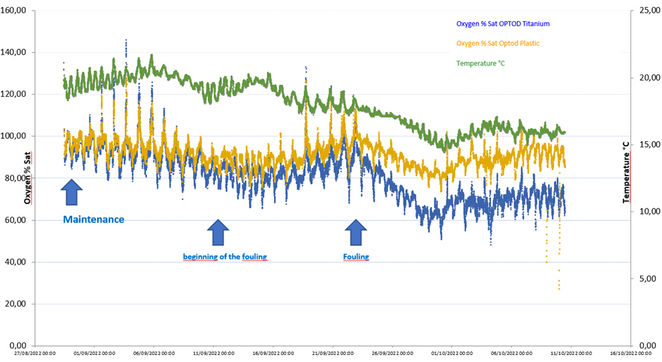

For more than half of the test period, temperatures were above 20°C, creating favourable conditions for the development of Biofilm and algae.

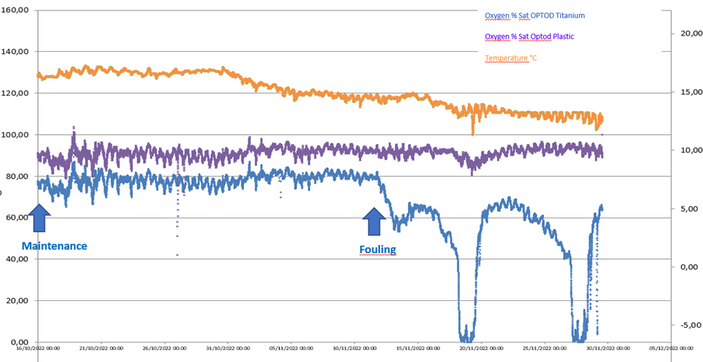

After 1 month, the OPTOD Titanium sensor (blue curve) begins to show measurement offsets while the plastic OPTOD sensor, with the anti-fouling strainer (yellow curve), continues to deliver consistent measurements. After 1 ½ months of immersion, the measurement of dissolved oxygen delivered by the titanium sensor, without anti-fouling protection, deviates significantly from the measurements delivered by the plastic OPTOD sensor making operation much less reliable.

The day/night cycles corresponding to the photosynthesis/respiration processes are still remarkable for both sensors however the data measured by the plastic OPTOD sensor with antifouling protection more reflect the dynamics of the medium.

Second measurement campaign from 10 October to 29/11/2022

After cleaning, the 2 sensors are reintroduced in seawater for a 49-day test campaign under the same conditions as the first test period.

The strainer of the OPTOD Titanium sensor and the DOdisk are completely covered with Biofilm and the measurements delivered by the sensor cannot be significant.

The anti-fouling strainer fitted to the OPTOD Plastic sensor is in very satisfactory condition after almost 50 days of immersion without maintenance. Cleaning the anti-fouling strainer is very easy to perform while cleaning the OPTOD Titanium strainer is more difficult, more invasive and could damage the DOdisk.

After about 1 month of immersion, the measurement of dissolved oxygen in %Sat delivered by the Titanium sensor (blue curve) completely stalls and is no longer reliable. The plastic OPTOD sensor equipped with the anti-fouling strainer continues to function properly after 50 days of immersion.

Conclusion

The Anti-fouling strainer is very effective in limiting biofouling formation on the DOdisk of the plastic OPTOD sensor, protects the membrane and ensures the continuity of dissolved oxygen measurements after almost 50 days of immersion without maintenance. The Anti-fouling strainer allows to optimize the manual cleaning frequencies of the DOdisk while preserving it from too aggressive maintenance risk to deteriorate it.